Features are as follows

Features are as follows

High speed reduction

High speed reduction

Accurate sliding motion

Accurate sliding motion

Helically cut for better mating

Helically cut for better mating

Highly efficient and accurate movement of load

Highly efficient and accurate movement of load

Size: - 1 1/8 to 10 (inches)

Size: - 1 1/8 to 10 (inches)

Shaft: - Solid / Hollow

Shaft: - Solid / Hollow

Mounting: - Foot / Flange

Mounting: - Foot / Flange

Reduction Ratio: - 5:1 – 70:1 for single reduction

Up to 4900:1 for double reduction

Reduction Ratio: - 5:1 – 70:1 for single reduction

Up to 4900:1 for double reduction

Horizontal (Under driven / Over driven)

Horizontal (Under driven / Over driven)

Vertical ( Upward / Downward )

Vertical ( Upward / Downward )

NU Series (Universal Casing)

NU Series (Universal Casing)

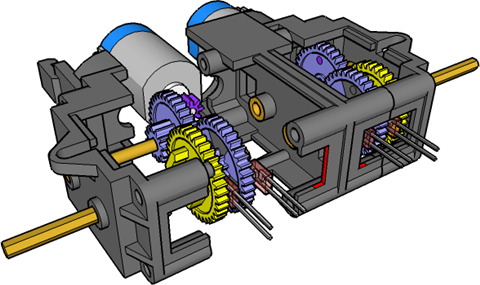

Double Reduction Gearbox

Double Reduction Gearbox

Tube Mill (Double Output, Single Input)

Tube Mill (Double Output, Single Input)

Design Features

Design Features

Housing: Cast Iron body providing maximum strength, dust proof.

Housing: Cast Iron body providing maximum strength, dust proof.

O/P Shaft: Output shafts are of High tensile steel and surface is grinded

O/P Shaft: Output shafts are of High tensile steel and surface is grinded

Bearings: Tapper Roller bearings are used.

Bearings: Tapper Roller bearings are used.

Oil Seals: JK Fenner Oil seals

Oil Seals: JK Fenner Oil seals

Interior of Housing is painted as it provides seal against corrosion and prevents contamination from casting

Interior of Housing is painted as it provides seal against corrosion and prevents contamination from casting

Worm Shaft: Worm shafts are made up of Alloy Steel, Case hardened and Thread profile grounded.

Worm Shaft: Worm shafts are made up of Alloy Steel, Case hardened and Thread profile grounded.

Worm Wheel: Worm wheel outer ring is of Phosphorus Bronze (PB 2). This copper tin alloy offers good shock resistance and strength.

Worm Wheel: Worm wheel outer ring is of Phosphorus Bronze (PB 2). This copper tin alloy offers good shock resistance and strength.

Salient Features

Salient Features  Cost Effective.

Cost Effective.

No other method provides the accuracy and repeatability of Hobbing process.

No other method provides the accuracy and repeatability of Hobbing process.

Profile ground worms provide high efficiency.

Profile ground worms provide high efficiency.

Providing high ratio speed reduction in minimal space.

Providing high ratio speed reduction in minimal space.

Some ratios have resistance to back driving.

Some ratios have resistance to back driving.

Efficiency is easily increased by lowering ratio.

Efficiency is easily increased by lowering ratio.

Smoothest and Quietest form of gearing.

Smoothest and Quietest form of gearing.

Packaging Machinery

Packaging Machinery

PET Blow Molding Machinery

PET Blow Molding Machinery

Material Handling

Material Handling

Food Processing

Food Processing

Conveyors

Conveyors

Machine tools

Machine tools

Many more…

Many more…

PROGEARSIVE’s NU series were developed to meet the demand for a compact, universal mount worm gear speed reducer. It is produced to offer industry unmatched dependability.

PROGEARSIVE’s double reduction units consist of two single reduction worm gear units. The primary worm gear unit is specially designed to mount integrally on a standard single worm gear unit which forms the secondary stage. Double reduction gear units are made up of same high quality components as single reduction.

PROGEARSIVE’s tube mill worm gear units use one worm on the power input shaft to turn two gears simultaneously in opposite directions. This gearbox is designed for applications such as cold-form rolling, tube mills, tyre curing press.